One of the largest industrial enterprises in Poland, Eurocast Sp. z o.o., has decided to join a number of initiatives aimed at helping Ukrainian refugees safely wait out the time of anxiety. Eurocast has implemented actions supporting Ukrainians who flee the war, both on the organizational and material levels by cooperating with the local government and the local community, as well as on the staff level by offering jobs and employment.

Due to the increasing influx of refugees into Poland, Eurocast has established cooperation with the local government in Łęczyce. The Company has decided to support the activities of the commune authorities in organizing help points for Ukrainians reaching this area. Additionally, the created aid points can also count on financial aid from the Company.

Still, immediate financial assistance is not enough. In order to ensure access to work and professional development for people from Ukraine who plan to stay longer in the area, the Company also offers jobs in various specialist positions. The Eurocast team welcomes employees such as machine operators, forklift operators, as well as technical workers.

– The successive development of Eurocast allows us to react efficiently in situations requiring immediate intervention. Among other things, one such situation is related to the suffering of our eastern neighbours, forced to leave their homeland for reasons completely beyond their control. Therefore – apart from material support – we decided to get involved in helping also from another side, for example by helping to organize the reception and care of refugees or by providing jobs for individual positions – says Krzysztof Wiśniewski, President of Eurocast.

Contact regarding assistance for people coming from Ukraine:

tel. 58 676 51 00

Eurocast launches new high barrier, fully-recyclable, EVOH-free packaging films

The freshness and quality of food products depends largely on how they are packaged and the type of packaging used to extend their shelf-life and thus prolong their usability. Properly packaged goods are resistant to the harmful effects of external factors that make them expire more quickly.

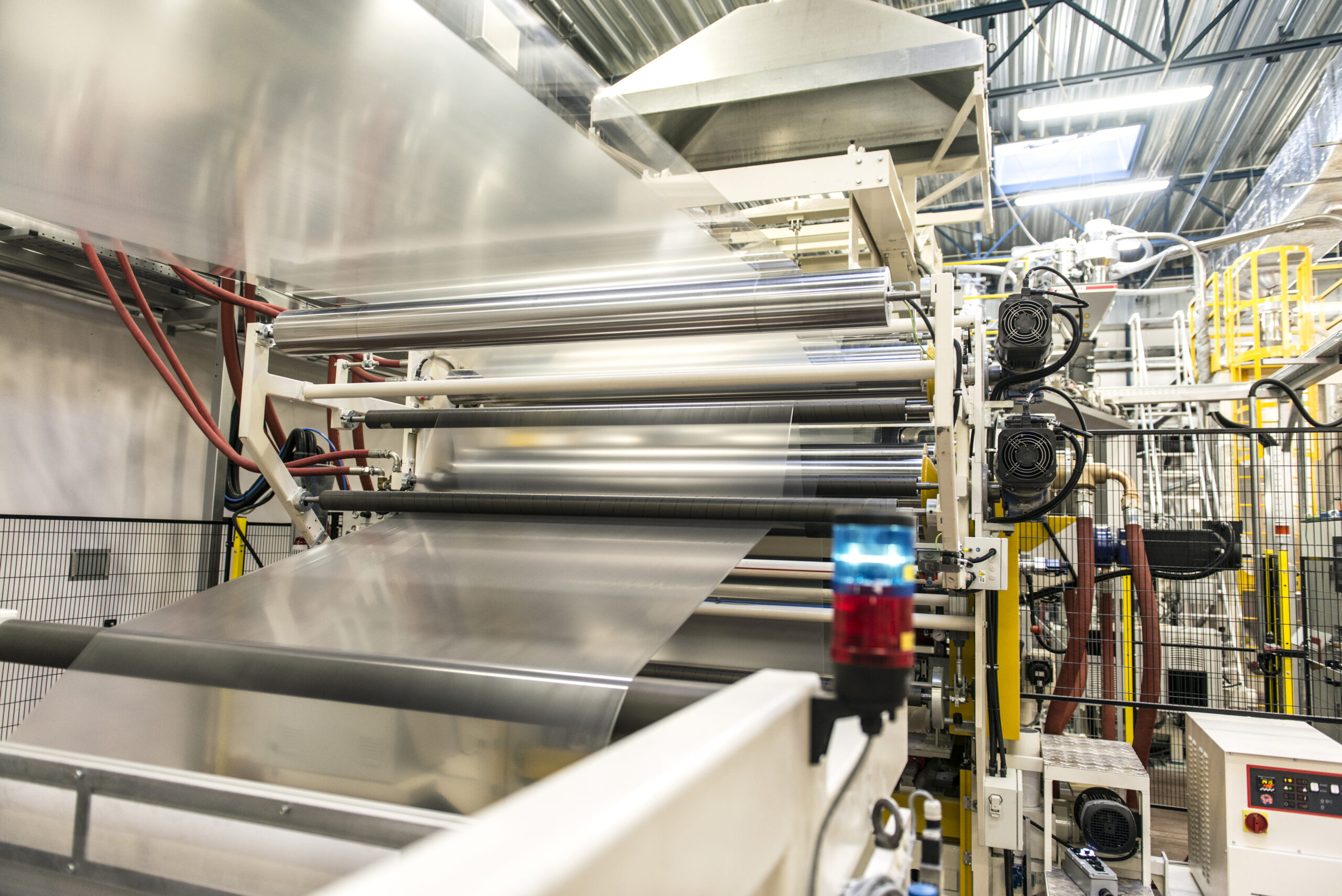

CRYSTA-LINE is a series of high-barrier mono-material films without an EVOH barrier layer, launched by Poland’s leading packaging manufacturer Eurocast. In their production process, transparent aluminium oxide (AIOx) coating technology is used. Consequently, the lamination of standard PET film with other materials such as PP film, PE/EVOH/PE film or aluminium has been completely eliminated, which has significantly reduced both the use of raw materials as well as the weight of the packaging.

Thanks to the composition of Eurocast’s new packaging films, the packaging made from them is fully recyclable, as certified by the Institute cyclos-HTP of Aachen (Germany). Following the independent certification process, the new CRYSTA-LINE series was classed as AAA+ and received a 100% recyclability label, which confirms that it is fully recyclable, while still retaining properties comparable to the original product. This means that the films developed by one of Poland’s leading industrial companies fully comply with the circular economy requirements.

The CRYSTA-LINE series includes CRYSTA-LID, CRYSTA-BASE and CRYSTA-LIDPP packaging films.

CRYSTA-LID is a mono-PET lidding film. As compared to commercially available EVOH-based products, it is characterised by low oxygen and water vapour permeability (OTR = 1 cm3/m2 in 24h and WVTR = 0.5-1 g/m2 in 24h). This is due to the use of transparent aluminium oxide (AIOx) coating technology, which provides a fully recyclable barrier. Additionally, CRYSTA-LID offers perfect protection of packaged food, optimal sealing parameters (SEAL, PEEL) and, in the AF option, excellent anti-fog properties. The certificate issued by the Institute cyclos-HTP confirms 100% recyclability of the product, which can be used for different types of food.

The CRYSTA-BASE film is based on mono-material APET. Designed for tray type packaging, it is used for packing food with a long shelf life. This includes in particular maturing cold meats, smoked fish or different types of cheese. The packaging manufactured from CRYSTA-BASE films is also perfect for preservation of fresh food. This is due to their high barrier properties, which are much better than those of similar products with an EVOH layer.

Another film from the CRYSTA-LINE series is CRYSTA-LIDPP. It is a lidding film that can be used for tray packaging made entirely of PP. Together with the PP trays, the CRYSTA-LIDPP film is fully recyclable.

The CRYSTA-LINE series provides a complete, environment friendly solution. Unlike the commonly used multilayer coextruded films, the new mono-material films launched by Eurocast are fully recyclable. Also, thanks to the elimination of the EVOH layer, the production of all CRYSTA-LINE films has a minimal impact on the environment.

Single manifold manual Flat die 1850 and Feed block 3-layer

Manufacturer: CLOEREN maker

(spare part: unused)

Contact person: Piotr Szymczak piotrszymczak@eurocast.pl

Phone: 0048601687859

We are soon going to boost our production capacity of APET rigid film from 22,000 tonnes to 30,000 tonnes per year!

EUROCAST has just signed an agreement for the purchase of a new APET rigid film production line with Italian company Costruzioni Meccaniche Luigi Bandera SpA. Installation and commissioning of the new line is planned for the third quarter of 2022.

“We continue to invest in new machinery so that we can quickly implement new innovative solutions to effectively develop our business in each segment of our operations,” commented Krzysztof Wisniewski, CEO of EUROCAST.

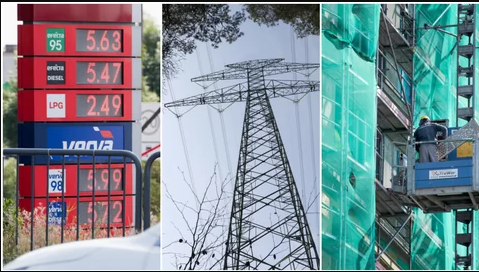

As wnp.pl informs, only a year ago the prices of raw materials used for plastics production recorded an unprecedented fall. Now there is no trace of it, raw materials are more expensive than ever, and there is no end in sight for the upward trend… This is a serious problem for the entire plastics sector

Poland remains an important market for European plastics processing. Our share in the European plastics consumption is about 7.7%. The main sectors using plastic products are still the packaging industry and construction – they account for about 60% of the total plastics use. All this makes our companies particularly vulnerable to price fluctuations and they are seriously affected by them.

As Robert Rosicki CFO at Eurocast, points out: “The sharp drop in profitability this year is the direct result of galloping raw material prices, whose rate of growth was impossible to predict and subsequently to be reflected in the product prices. The same problem was faced by other processors operating on the plastics market, which is why profitability has declined across the entire industry.”

https://www.wnp.pl/chemia/tak-drogo-w-chemikaliach-nie-bylo-jeszcze-nigdy,480060.html

The end of the first edition of the cancer awareness programme “ONKOODPOWIEDZIALNI” fills us with optimism and satisfaction

A total of 100 ompanies have joined the action raising awareness of gynaecologic cancers. As a proud partner of the programme, Eurocast is pleased to be able to take part in it.

We would like to thank the organizers for very insightful meetings with medical professionals and the opportunity for our employees to have free cancer screening tests. This reminded all meeting participants how important it is to take care of their own health through regular preventive healthcare.

With the next edition of “ONKOODPOWIEDZIALNI” coming soon, we are very happy to encourage other socially responsible employers to join the programme. We encourage you to follow the campaign at www.onkoodpowiedzialni.pl

The plastic restriction associated with the EU SUP Directive will not be legally binding as of July 3

The legislative process has been delayed, but some companies have already started the costly process of re-profiling their operations and replacing machinery. What’s more, the plastics industry is facing a black cloud of a new tax, which from 2021 will amount to €0.8 for every kilo of plastic not processed.

Robert Rosicki, Member of the Board and CFO of Eurocast, explains to Dziennik Gazeta Prawan that at the moment the above-mentioned tax is covered by the state budget, but ultimately the cost will be borne by entities introducing plastic packaging to the market, and this will significantly affect the cost of manufactured products.

Read more: https://biznes.gazetaprawna.pl/artykuly/8201690,dyrektywa-plastikowa-jednorazowki-ograniczanie-uzywania-plastiku.html

The 16th edition of Street Challeng Sopot is behind us

On the 22nd of June there was a wonderful, intergenerational, sporting celebration. Street Challenge Sopot 2021 can be called a great success and we are glad that Eurocast, as a sponsor, could be a part of it.

We congratulate all the winners and thank all the great participants. We hope to see you next year during the next edition

Is there a chance that Eurocast will produce films only from recyclates?

We made a milestone in the production of films from recycled materials back in 2014 by investing in decontamination technology for recycled materials. Decontamination is designed to remove substances from recycled plastic that are harmful to humans and the environment, as well as any other “contamination” of the material. In accordance with EFSA and FDA standards, we get a high-quality, food-grade post-consumer raw material – so packaging can be made from 100% recycled plastic.

The fact is, however, that the mere desire to use recyclates won’t help much if they are not available to manufacturers. At present, it is difficult to source the quantities of recyclates that would cover our production capacity.

Read more about the changes and future plans at Eurocast at: Eurocast – wzrost w warunkach rynkowego niepokoju – Ekonomia – rp.pl

What is getting the most expensive? These are the main culprits behind inflation

In May, we recorded the highest inflation rate in 10 years, and as a result, absolutely everything became more expensive – the entire industry included.

Raw materials in the plastics market have reached unprecedented price values this year. PET, the most popular in production, has increased in price by more than 60 percent compared to its price at the end of 2020, and polypropylene has risen even more. However, the absolute phenomenon is the granulates of the commonly used polyethylene, whose prices have increased by more than 100 percent.

Today, plastics are not only used to produce packaging for food, medicine and household chemicals, but also to manufacture the majority of clothes, shoes, household items, furniture and the automotive industry is one of the key industries in terms of plastics consumption. It is hard to think of any industry where plastics are not a key raw material, which is why such high inflation is a bad sign for all of us. More expensive materials have a direct impact on product prices, which in turn affects customers.

The entire industry is in a difficult situation, but more about it on: https://businessinsider.com.pl/wiadomosci/co-najszybciej-drozeje-oto-glowni-winowajcy-inflacyjni/hm3sxzs